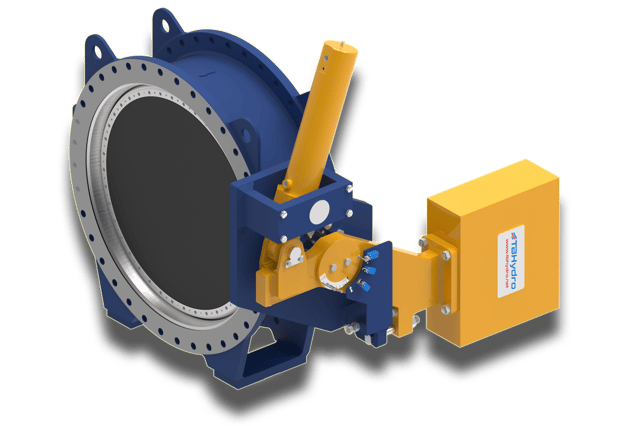

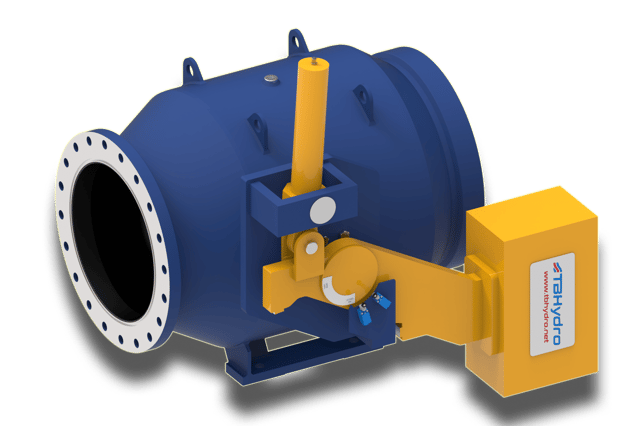

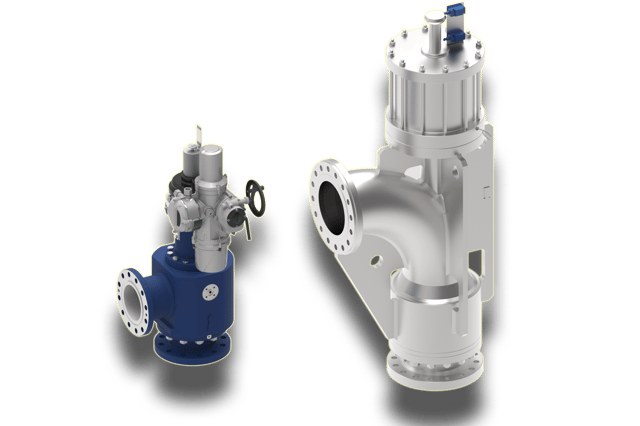

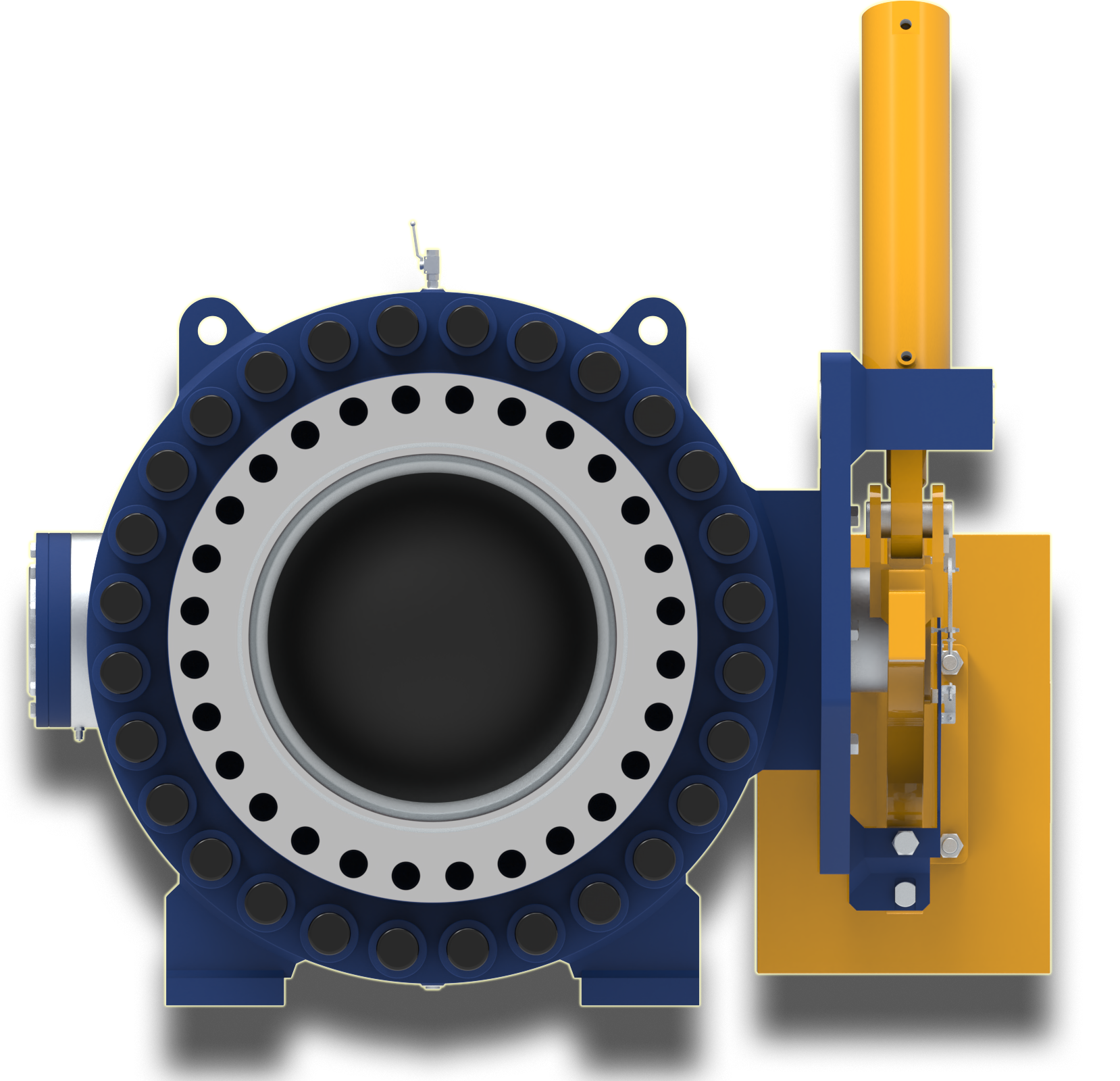

Ball valves

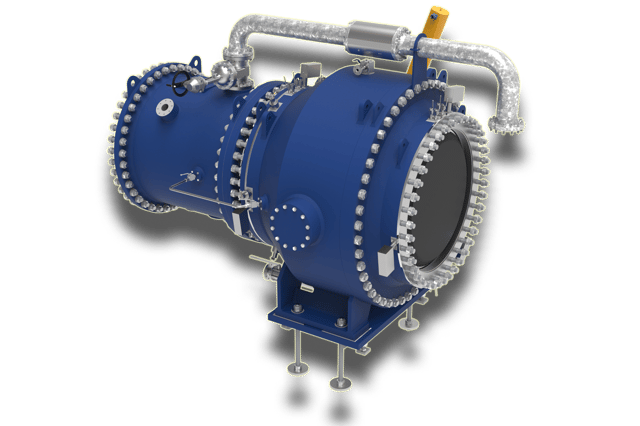

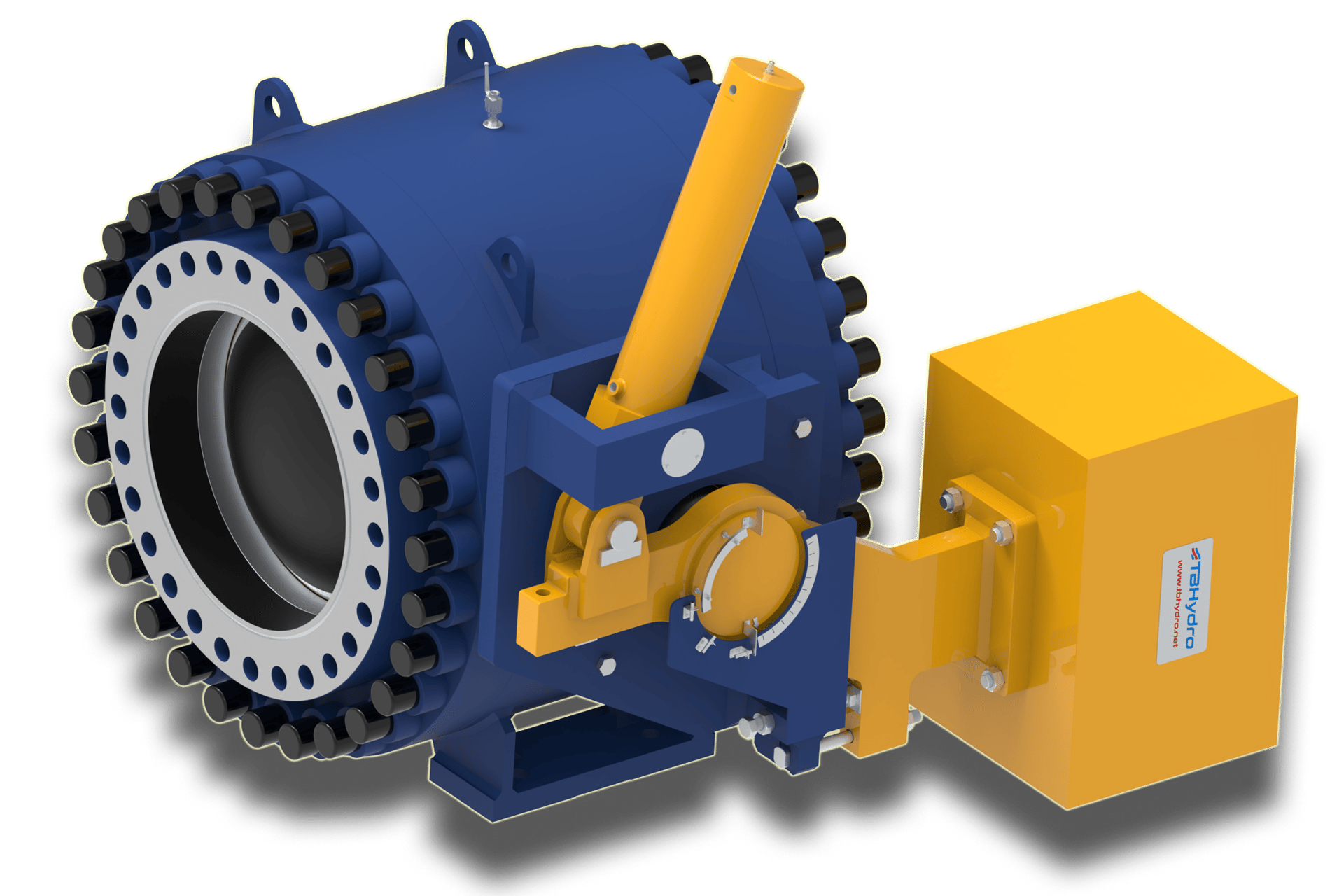

Ball valves of type BLV and SPV are designed for shutting off the flow of water and other media in high-pressure pipeline systems within hydroelectric power plants. TB Hydro designs, manufactures, and services this type of ball valve.

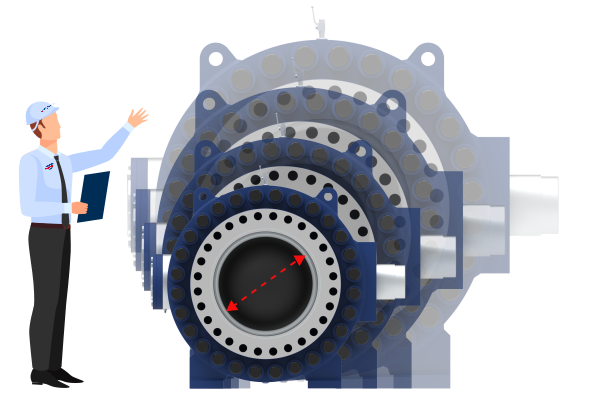

Diameter:

Wide range of diameters from 150 to 2000 mm.

Pressure:

Pressure range from 6 to 200 bar.

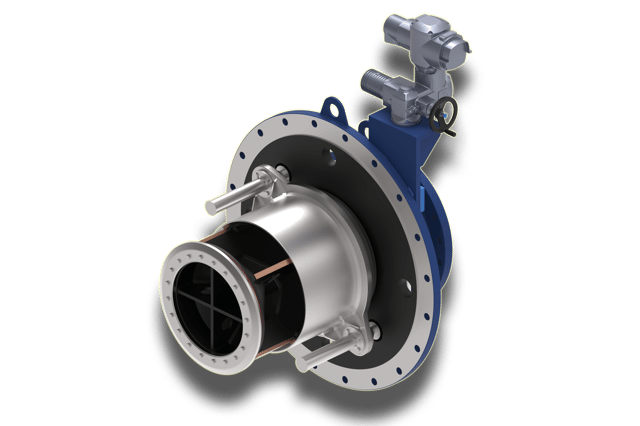

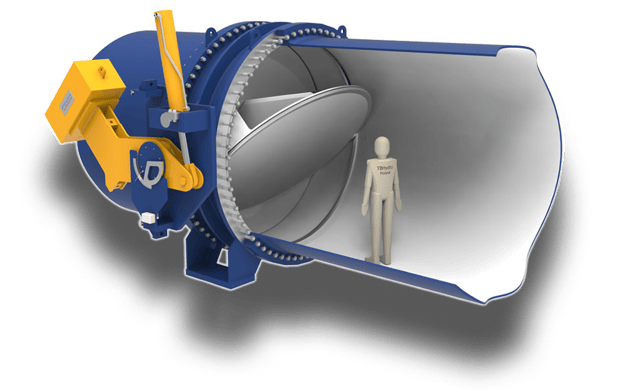

Ball valve design

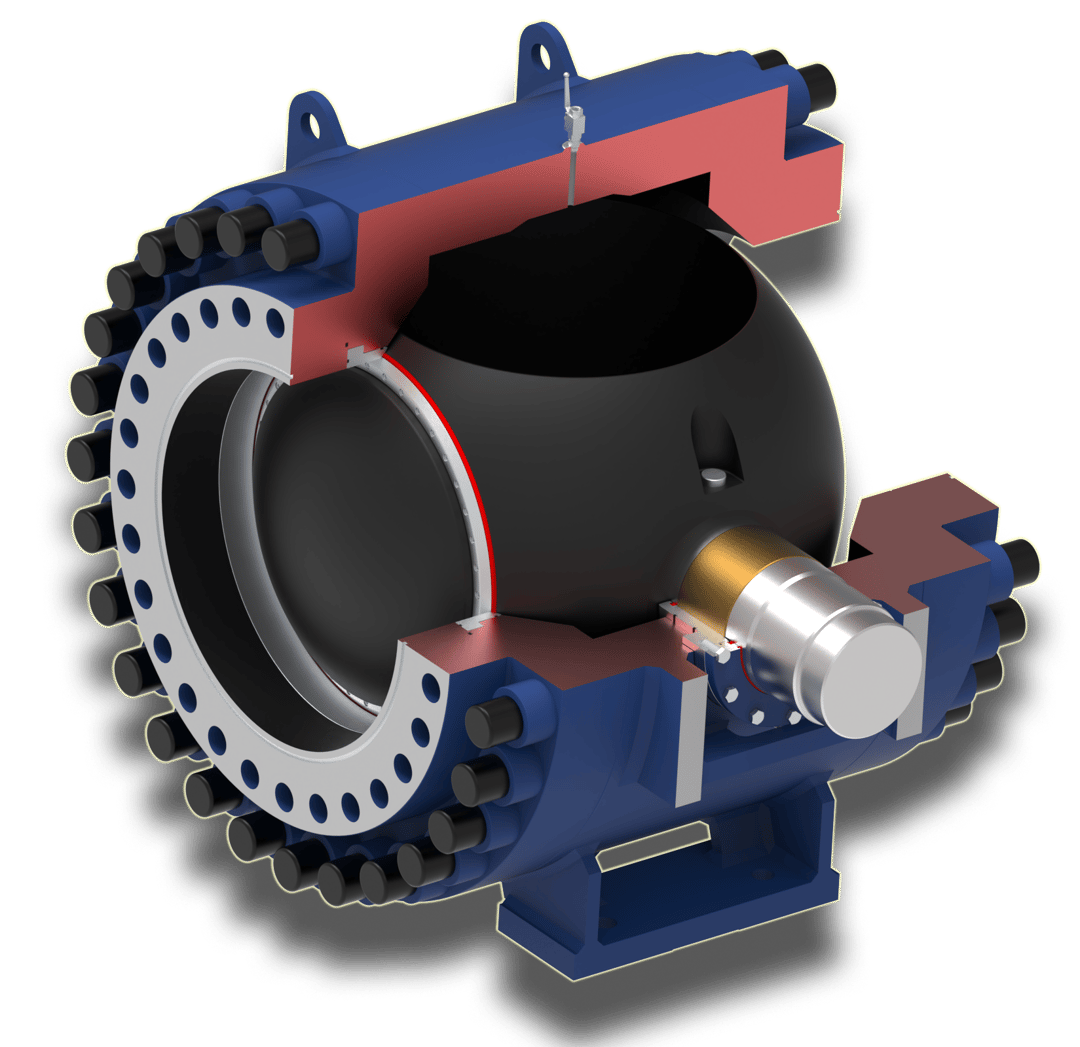

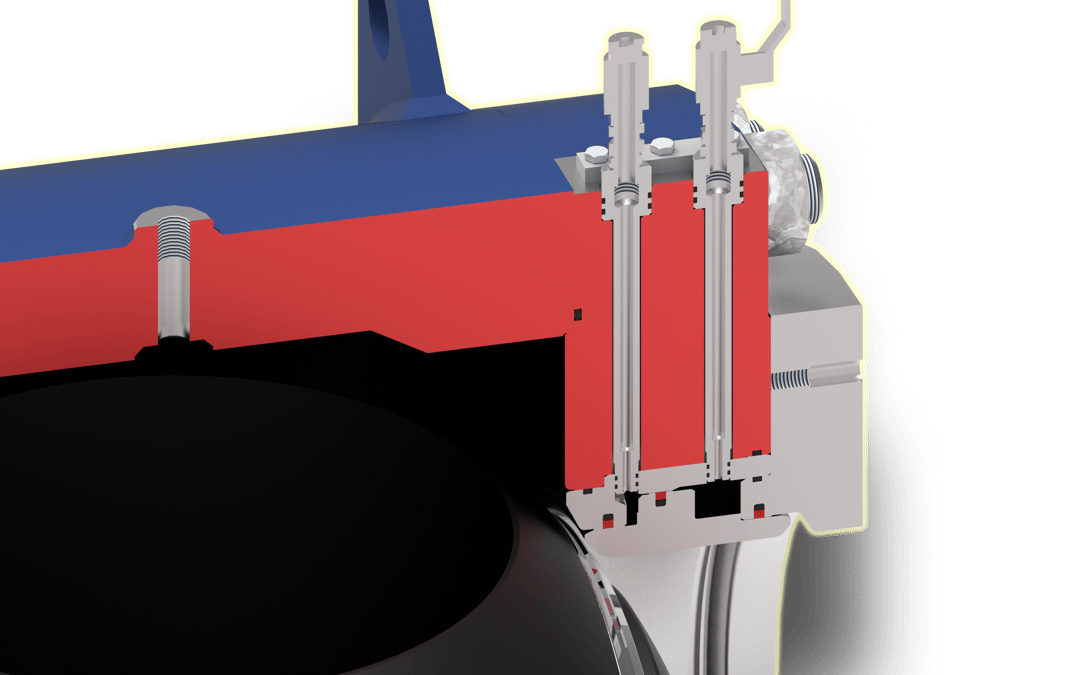

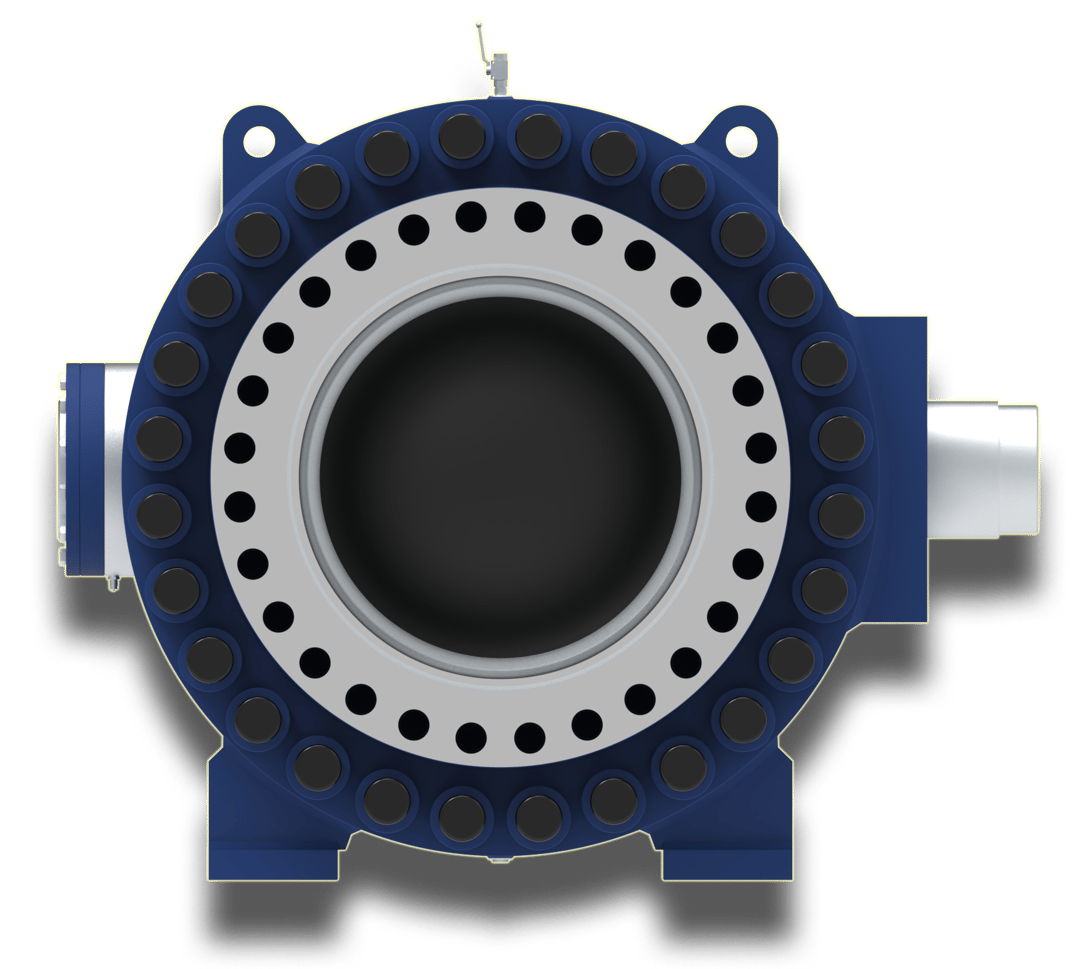

Body

The body can be in a 2- or 3-piece design. It is available in the following versions welded from plates and forgings, bolted from forgings and cast

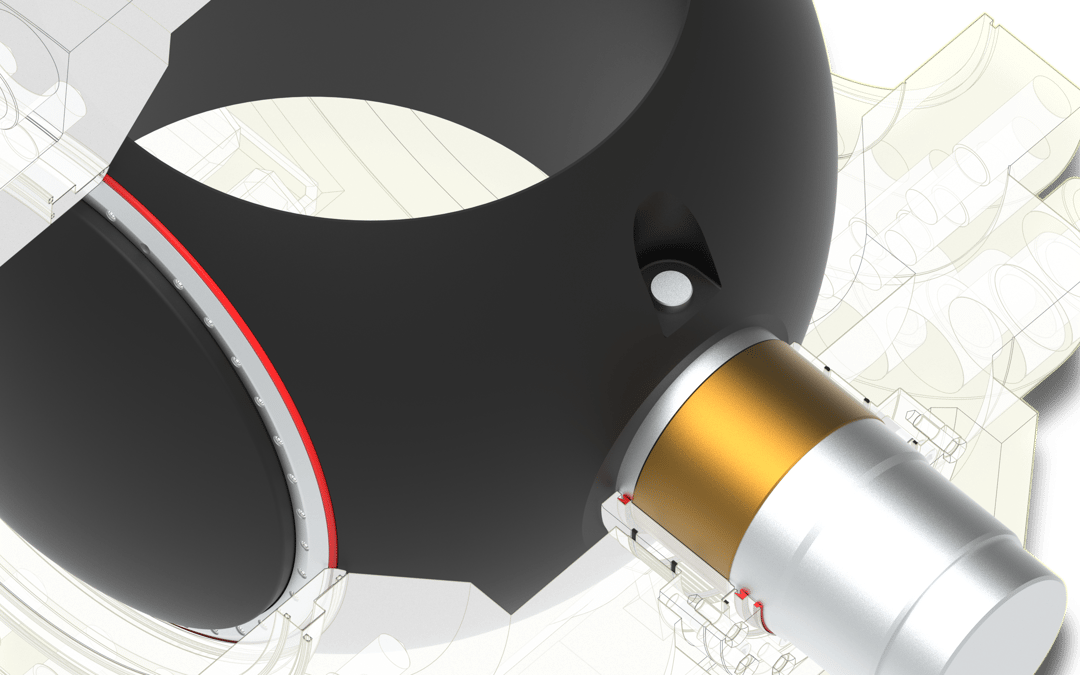

Ball

The ball, as the closing element, can be manufactured as a welded, forged, or cast component. In every variant, the ball features a full bore.

Main Seal

- Type BLV soft seal - a polyurethane profile secured to the ball by a clamping ring. The mating surface in the body is made as a stainless, replaceable ring.

- Type SPV metal/metal seal - A movable stainless ring seated in the body, water-controlled, cooperating with a stationary stainless ring seated in the ball.

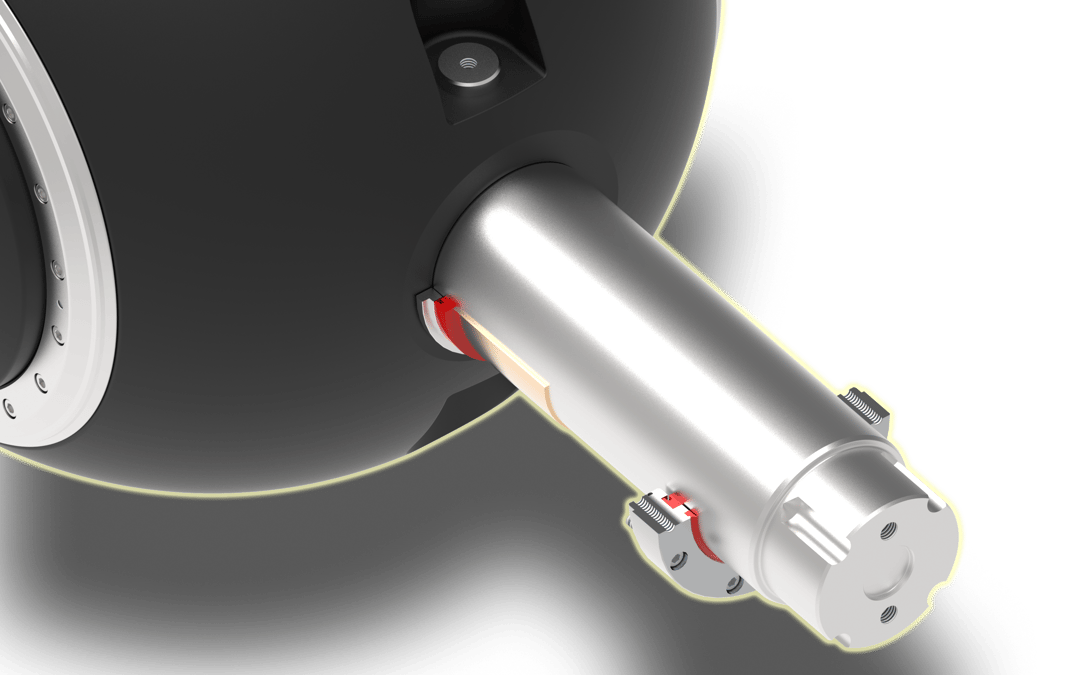

Maintenance Seal

- metal/metal - A movable stainless ring seated in the body, water-controlled, cooperating with a stationary stainless ring seated in the ball.

Shafts

Stainless steel shafts are rigidly connected to the ball using pins or bolted with tensioned screws, in which case torque is transmitted via bushings.

Bearings

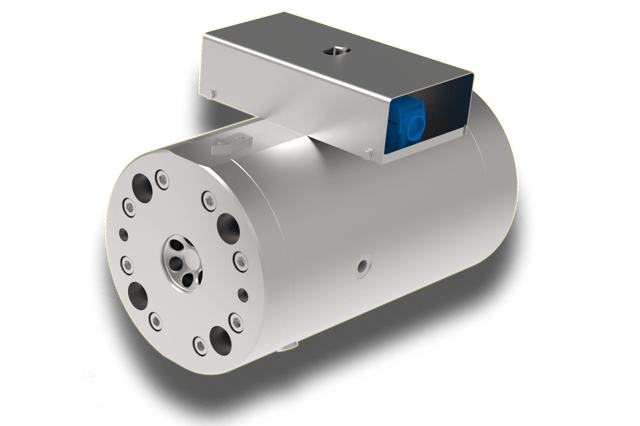

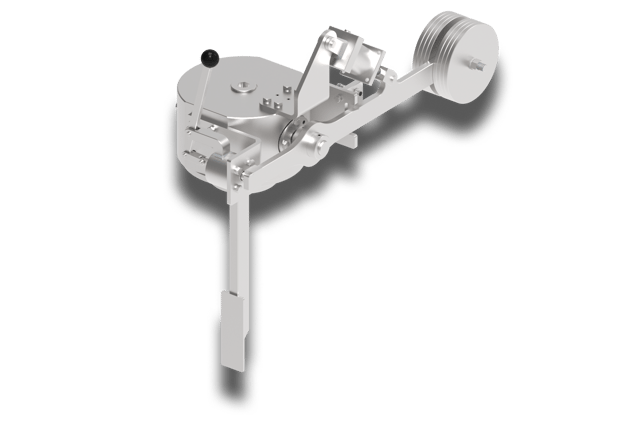

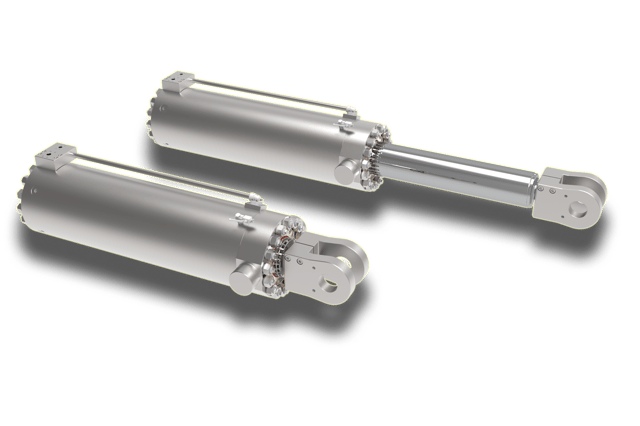

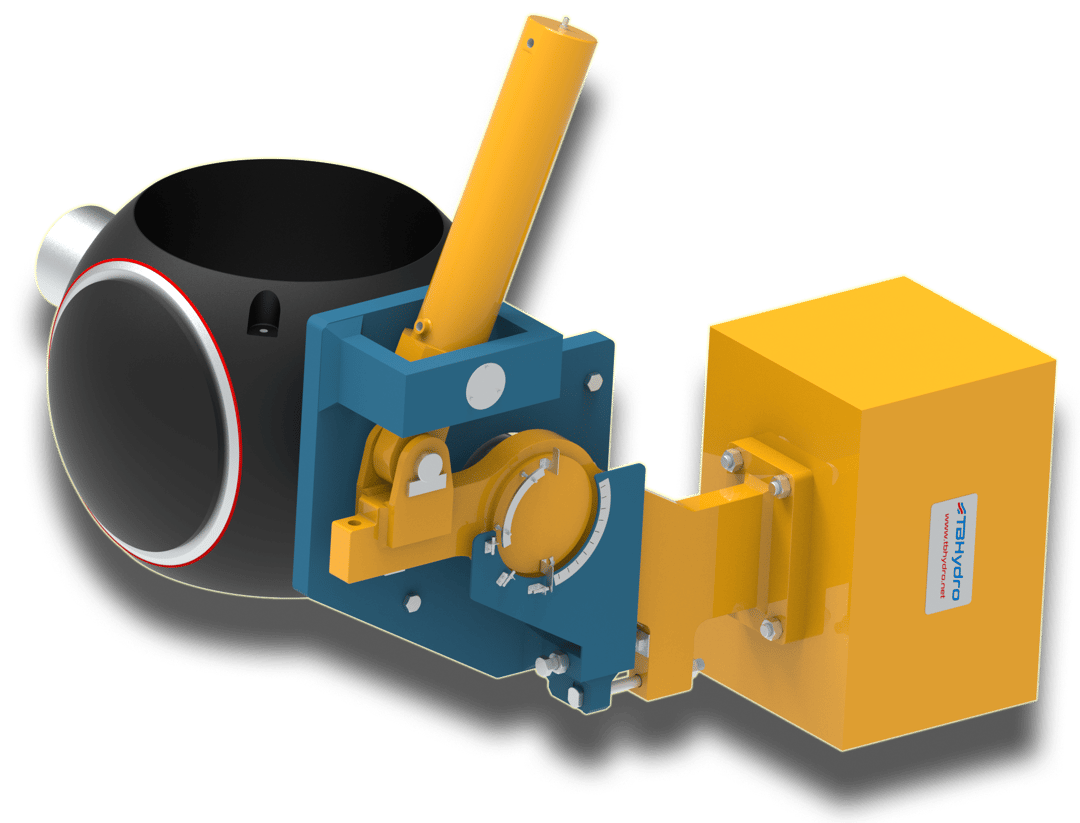

Actuator

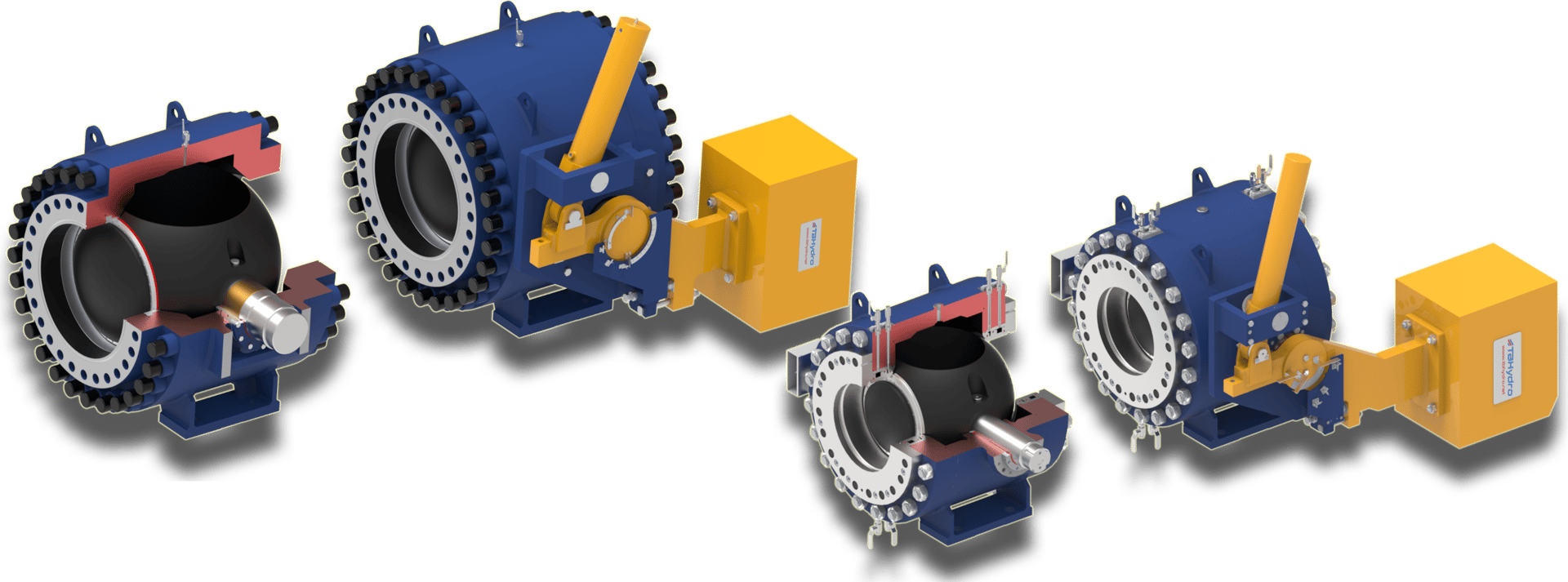

The actuator can be:

- Single-sided, mounted from any side

- Double-sided

Standard configurations include:

- A counterweight for closing and a single-acting hydraulic cylinder for opening. The direction of the counterweight's descent is adjustable.

Optional actuators:

- Double-acting hydraulic or water cylinder

- Hydro-oil cylinder (water for closing, oil for opening)

- Electric actuator with worm gear

- Manual actuator with worm gear

Ball Valve Types and Equipment

Ball Valve Types:

Ball Valve Types:

- Type BLV - ball valve with a soft seal and eccentrically mounted ball.

- Type SPV - ball valve with a metal/metal seal and centrally mounted ball.

Both types can come in the following versions:

- 2-piece body: welded, forged, or cast

- 3-piece body: forged

- With or without an inspection seal

Standard Ball Valve Equipment:

- Connection flanges typically with threaded holes, or optionally with through-holes

- Legs

- Lifting lugs

- Vent and drain ports

- Limit switches for closed/open positions

- Visual position indicator

- Mechanical lock in the valve's closed position

Optional Ball Valve Equipment:

- Additional connections

- Mechanical lock in the open position

- Additional electrical and hydraulic equipment, terminal box, hydraulic hoses

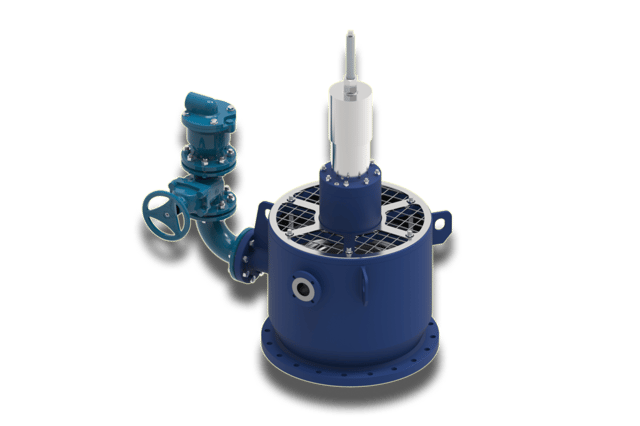

- Water control system, filters, sand separator (settling tank)

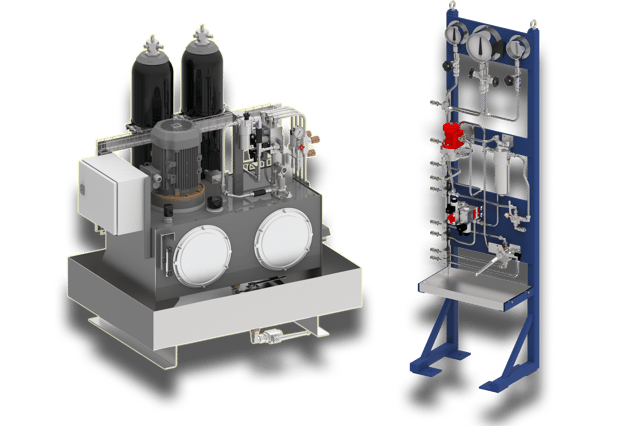

- Oil hydraulic control system

- Hydraulic power unit

- Electrical control panel

- Additional bearing sleeves allowing bearing removal without valve disassembly

- Bearings with emergency lubrication capability

- Automatic lubrication systems

- 2-stage actuator with adjustable valve closing characteristic

Materials

Basic materials used in our products. Other materials may be used according to customer requirements and their suitable application.

| Element | Type | Material |

|---|---|---|

| Bodies, Closing Elements | Plates | S355J2+N |

| Forgings | S355J2G3 | |

| Pipes | S355J2H | |

| Castings | G20Mn5 | |

| Shafts, Pins | Rods | 1.4021 / 1.4313 / 1.4418 |

| Sealing Surfaces | Plates | 1.4301 |

| Flat Bar | 1.4301 | |

| Soft Main Seals | Bonded Cord - Special Profile | NBR 80Sh |

| Machined Gasket / Lathe-Cut Seal | Polyurethane | |

| Metal Main Seals | Plates | 1.4301 |

| Forgings | 1.4006 / 1.4021 / 1.4057 / 1.4301 / 1.4313 | |

| Bolts, Nuts | Contact with Air | 8.8 / 8 Galvanized Steel |

| Contact with Water | A2-70 / A4-80 | |

| Bearings | Maintenance-Free, Self-Lubricating | - |

| Corrosion Protection | 2-Component Epoxy Paints | - |