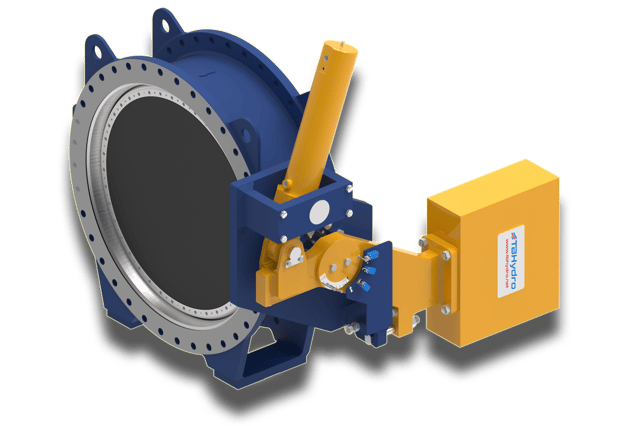

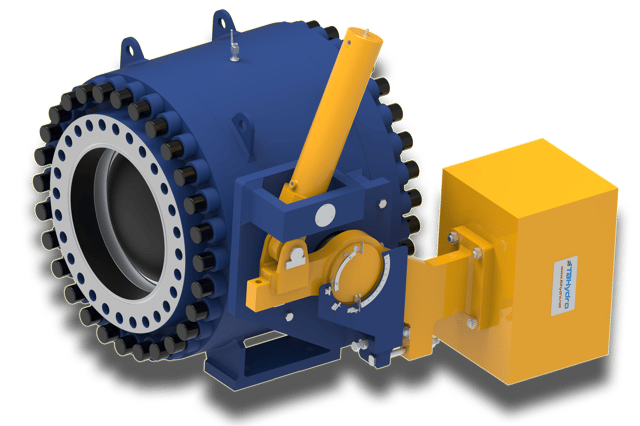

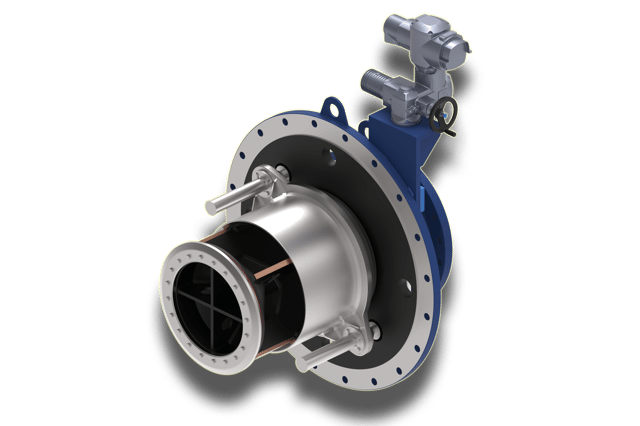

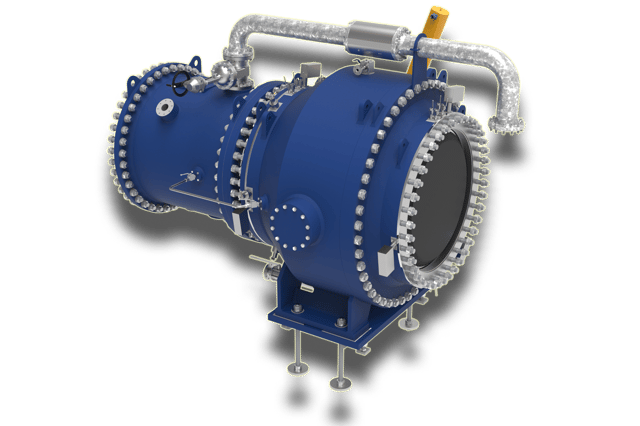

OVD Type Flow Detector

The maintenance-free mechanical detector is designed to detect and signal increased water flow in pipelines. Optionally, it can be equipped with a control valve for flow shut-off in the pipeline. Detectors are always designed according to individual customer requirements.

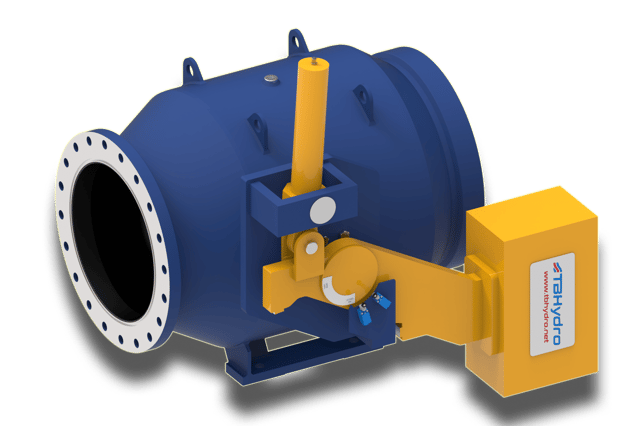

Diameter:

Nominal diameters: DN100 mm and DN150 mm.

Pressure:

Operating pressure range: 2.5 to 100 bar.

Medium:

Water - temperature up to 70°C / other applications and media available upon request.

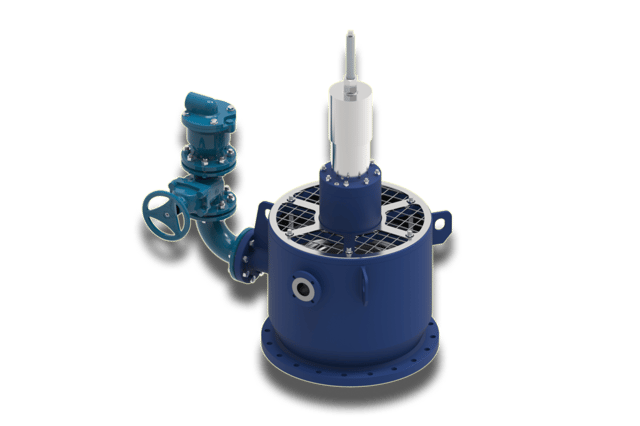

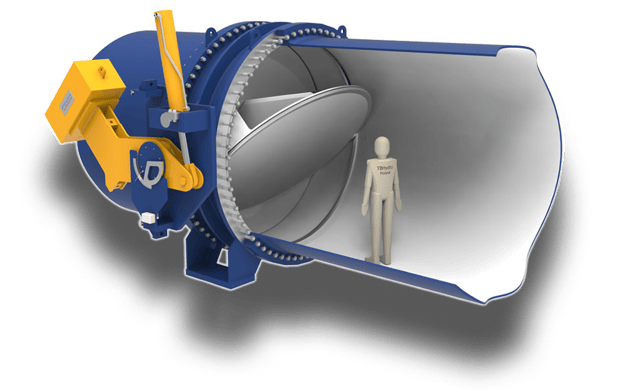

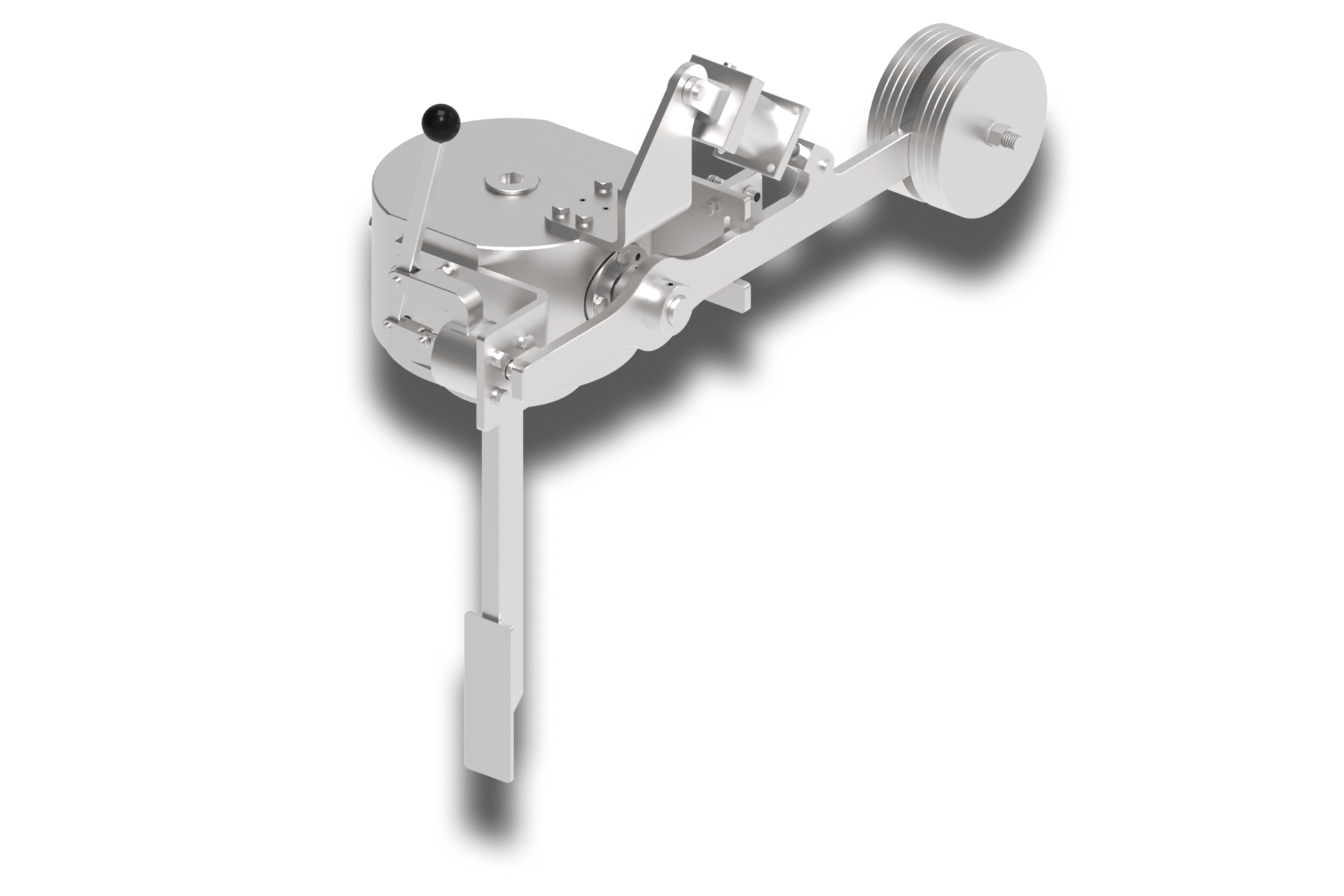

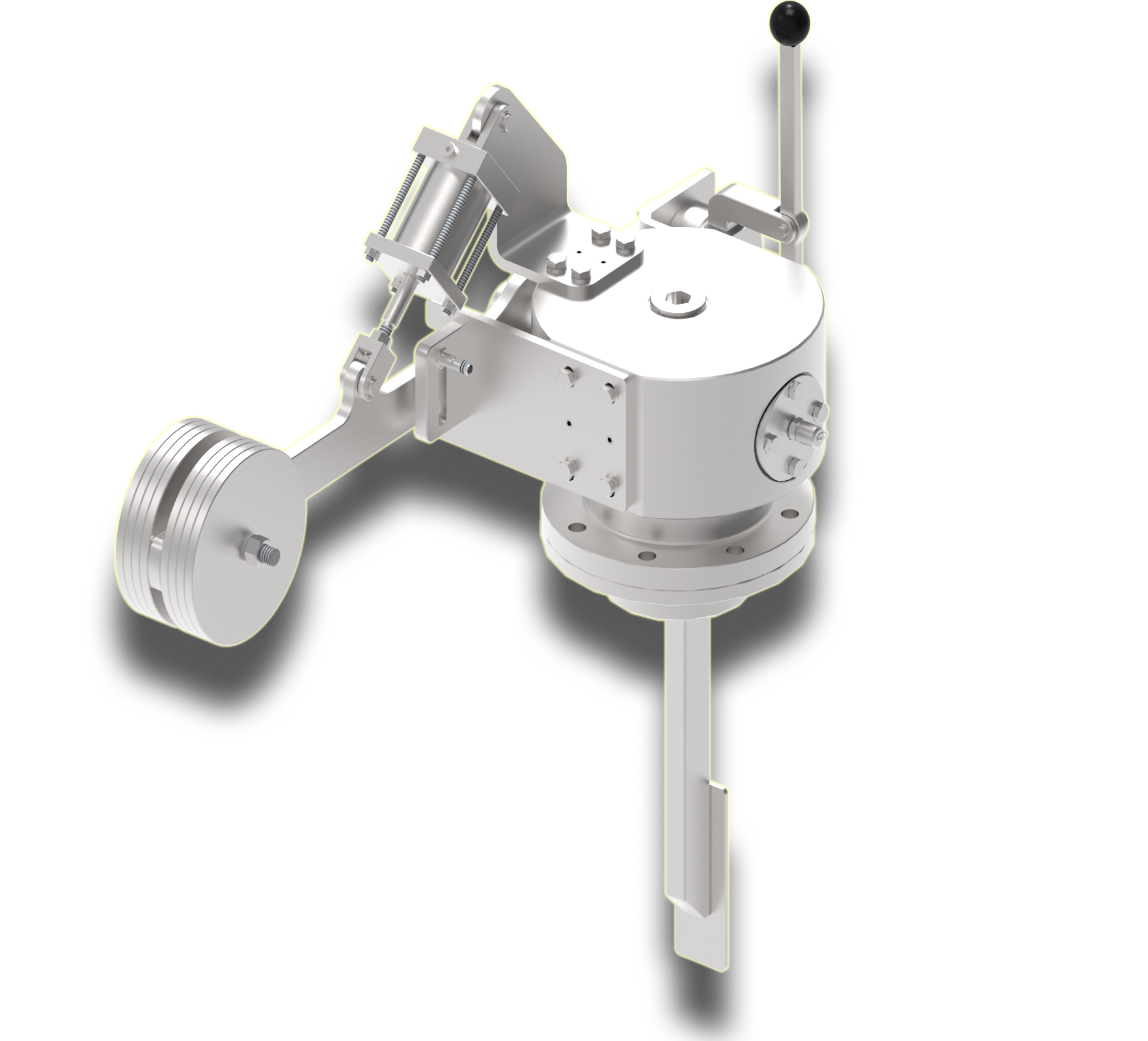

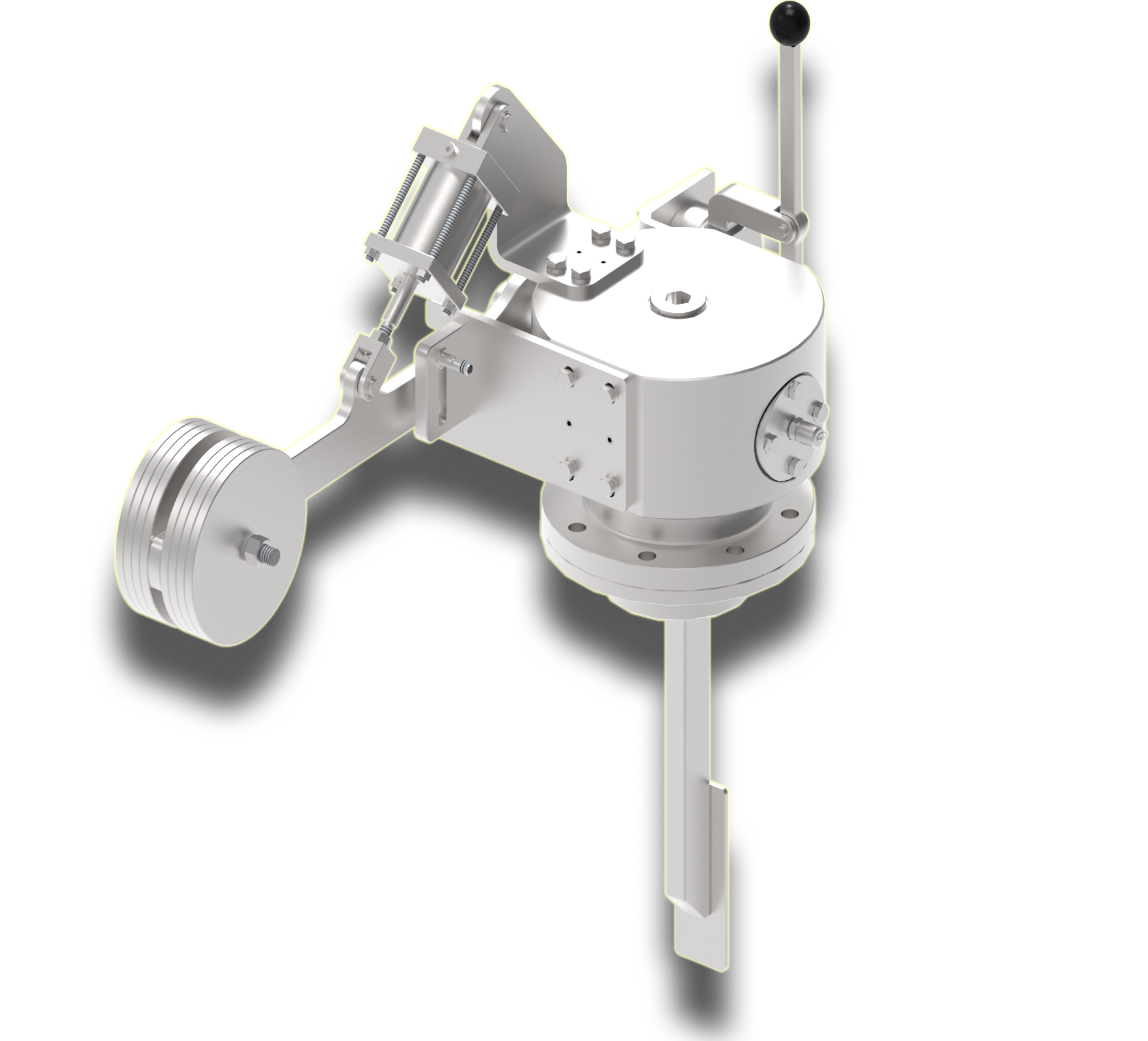

Flow Detector Design

Operation Description:

- An active lever with a plate is positioned inside the pipeline.

- The torque from the water pressing against the lever's plate is transferred via a shaft (with bearings) to a counterweighted lever.

- The size of the counterweight is calibrated during testing to ensure the lever deflects at a precisely defined flow rate.

- The deflection of the lever activates a limit switch and an optional hydraulic valve.

- In the deflected position, the lever is secured by an optional lock, which is released manually.

- An optional damper minimizes lever deflection caused by momentary flow disturbances.

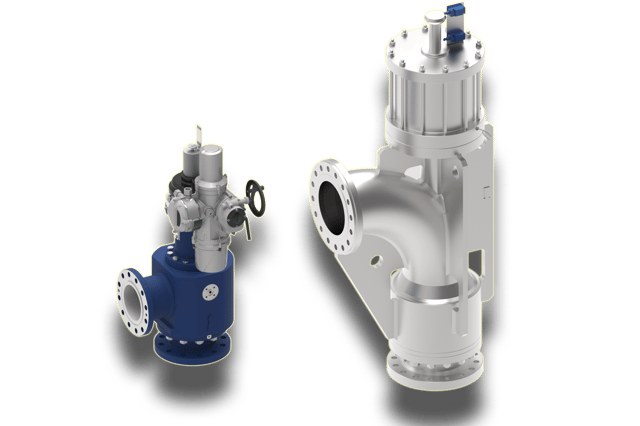

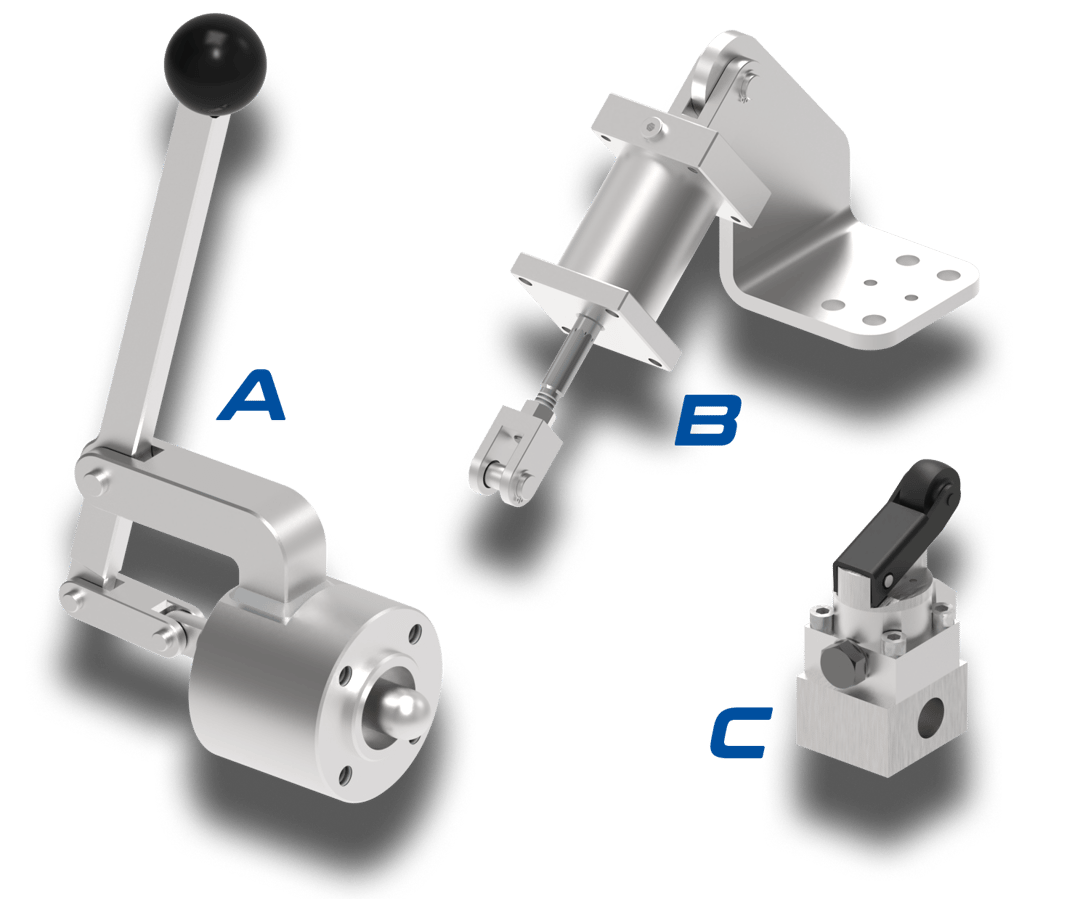

Additional Equipment

- A - Lock

- B - Damper

- C - Hydraulic valve

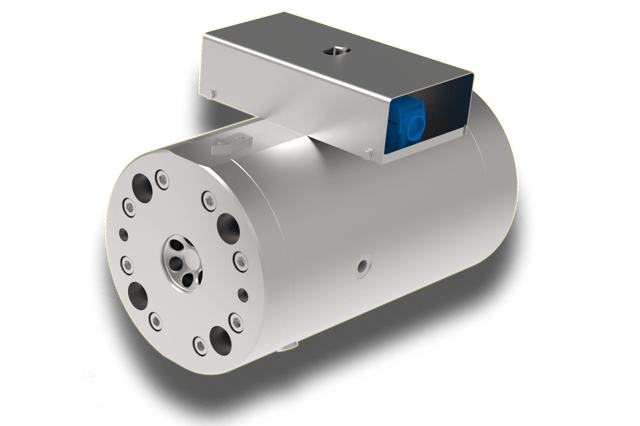

Standard and Optional OVD Detector Equipment

Standard Equipment:

- Limit switch for signaling increased flow

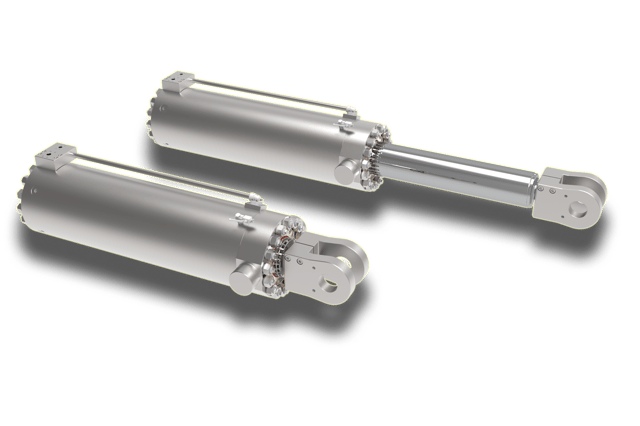

Optional Equipment:

- Hydraulic control valve for the shut-off valve in the pipeline

- Cabling and terminal box

- Additional hydraulic and electrical equipment

- Oil damper

- Lock

- Adapter for mounting on non-standard connections

Materials

Basic materials used in our products. Other materials may be used according to customer requirements and their suitable application.

| Element | Type | Material |

|---|---|---|

| Body | 1.4021 / 1.4313 / 1.4418 | |

| Shafts, Pins | 1.4021 / 1.4313 / 1.4418 | |

| Bolts, nuts | Contact with Water / Air | A2-70 / A4-80 |

| Bearings | - | - |

| Internal Lever | Plate | 1.4301 |

| Counterweight and External Lever | Plate | Carbon steel, optionally stainless steel |